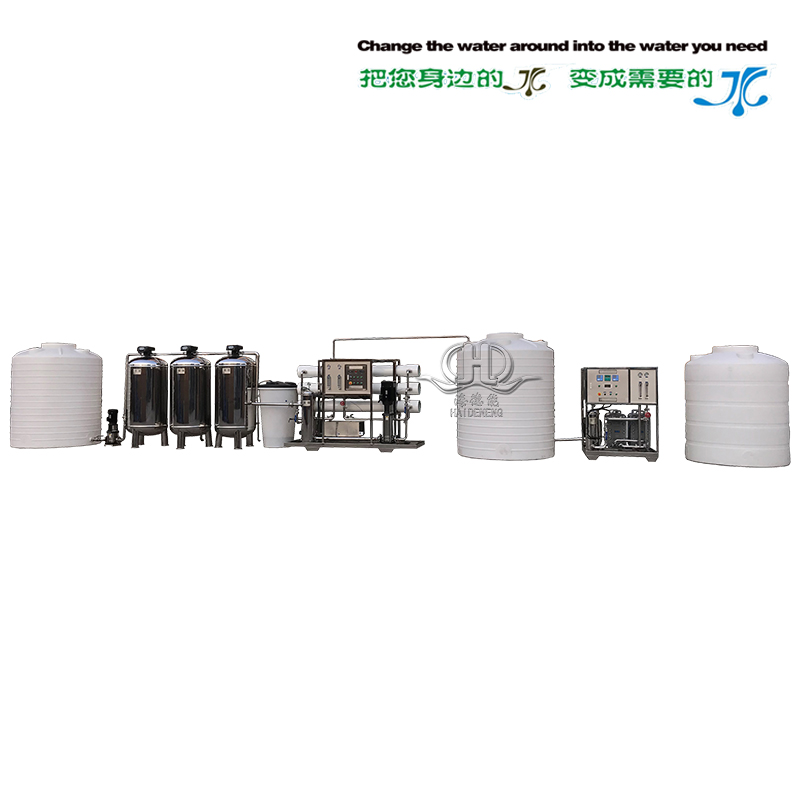

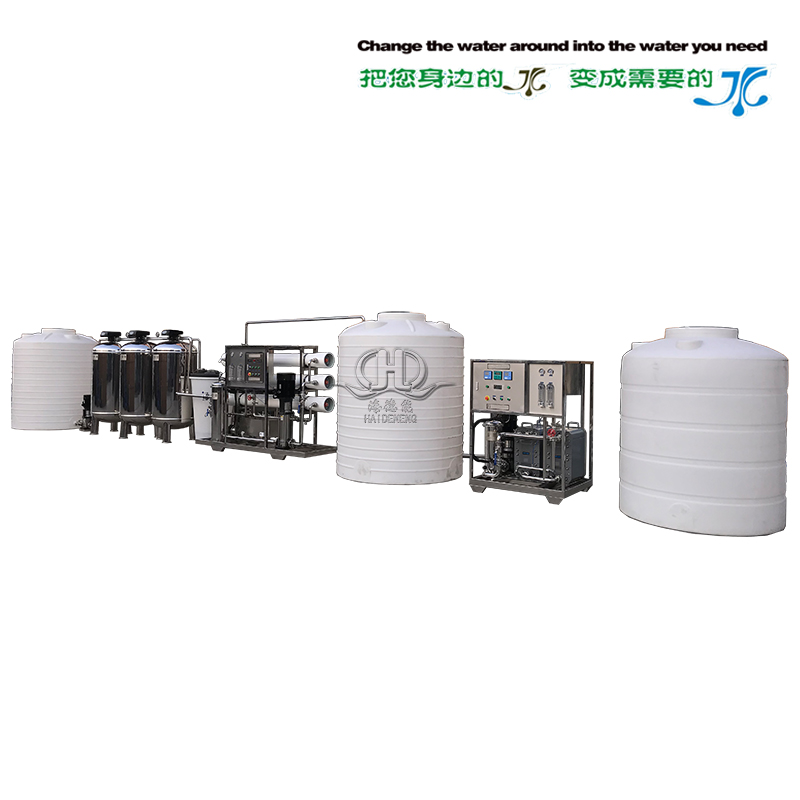

1、Equipment name: Automatic reverse osmosis +EDI ultra-pure water equipment

2、specifications and models:HDNRO+EDI-6000L

3、Equipment brand: Wenzhou Haineng wzhdn

4、Product function description:

1. Mechanical filter:

It is mainly used to remove rust, sediment, algae, suspended solids and other impurities in the water, reduce the turbidity of the water, make the turbidity of the water less than 0.5ntu, CODMn less than 1.5mg/l, iron content less than 0.05mg/l, SDI ≤ 5. The control valve can be used for back washing and forward washing at any time to wash off the dirt on its surface, prevent it from blocking and restore its filtering capacity.

gd55光大彩票2. Activated carbon filter:

Activated carbon has a very strong adsorption and filtration performance, and has a strong adsorption effect on residual chlorine, heterochromatic, peculiar smell, organic matters, etc. in water. As the reverse osmosis membrane is very sensitive to residual chlorine and organics, it is necessary to configure activated carbon to absorb residual chlorine and organics, so that the residual chlorine in the outlet water is ≤ 0.1mg/l, SDI ≤ 4, the first can meet the water supply requirements of the reverse osmosis membrane. Second, it can greatly improve the original taste of the source water. It can be backwashed at any time through multi-channel control valve or steam operated butterfly valve to wash away the colloid and other pollutants on its surface, prevent the surface of the activated carbon from being surrounded by impurities, prevent it from blocking, and restore its treatment capacity.

3. Softener:

The hardness of water mainly consists of cations: Ca and Mg. When the raw water with hardness passes through the cation resin layer of the softener, the calcium and magnesium ions in the water are absorbed by the resin, and the sodium ions are released at the same time. In this way, the water flowing out of the exchanger is the softened water with hardness ions removed. When the resin adsorbing calcium and magnesium ions reaches a certain degree, the exchange capacity will be lost. At this time, the softener will automatically regenerate the failed resin according to the predetermined procedure, and use the sodium chloride solution with higher concentration to pass through the resin to restore the failed resin to sodium resin.

4. Security filter:

After pretreatment, a safety filter is arranged in front of the high-pressure pump to prevent the impurity particles larger than 1um from entering the high-pressure pump and damaging the high-pressure pump and reverse osmosis membrane. The PP filter element (with framework and good strength) is loose outside and tight inside, and the water is filtered from the outside to the inside, which can prolong the time when the filter element is blocked. The upper part has an exhaust valve, which can prevent air from entering the pump and damaging the pump. The lower part has a drain valve, which can discharge the retained impurities at any time.

gd55光大彩票5. RO unit:

Reverse osmosis technology is a mature desalination technology in the world at present, and it is also a water treatment technology with wide market application and wide application range. It can filter bacteria, viruses, metal ions, salts, pesticides and all kinds of carcinogens in water precisely. It has low working pressure, large water yield and high desalination rate. It is easy to maintain and design automatic washing device, which can prolong its service life. The design of automatic flushing device can prolong its service life.

gd55光大彩票6. Terminal filter:

The microporous membrane with absolute pore diameter of 0.22um can completely remove the microorganism and its heat source, ensure the asepsis of water supply and meet the requirements of pharmaceutical water

gd55光大彩票7. Ultra pure water equipment (electric desalting EDI device):

gd55光大彩票EDI electric desalting device, as the equipment for ultra pure water production and as the secondary desalting equipment after reverse osmosis equipment, can produce up to 10-18.2m Ω / cm. Therefore, it is widely used in microelectronics industry, semiconductor industry, solar photovoltaic, fine chemical industry and power generation industry, pharmaceutical industry and laboratory. It can also be used for pharmaceutical distilled water, food and beverage production water, boiler make-up water of power plant, and other applications of ultra-high purity water.

gd55光大彩票8. PH regulating device:

gd55光大彩票As the water produced by reverse osmosis is slightly acidic and the pH value after secondary reverse osmosis is small, in order to meet the process demand, and the membrane element requires that the water inflow is the best neutral, which is of great benefit to the long-term stable operation of the secondary reverse osmosis membrane and the desalination rate and water production. Therefore, it is necessary to adjust the pH of feed water alkali dosing to neutral before the secondary reverse osmosis membrane. Automatic dosing with German ardoux or American Milton rowmetering pump, accurate metering and reliable dosing. The dosage is about 2-5ppm.

5. Features:

◇ RO membrane automatic and manual operation / flushing, optional touch screen control, human-computer interface.

◇ RO membrane can be cleaned manually with chemicals in the machine

◇ high water level automatic shutdown and low water level automatic startup of ultra pure water

◇ Multi stage high-pressure pump water shortage protection and overload and overpressure protection function

◇ voltage loss, undervoltage, overcurrent, short circuit, open circuit, leakage protection

◇ the equipment is made of stainless steel, fully automatic operation, and no need for manual conduct.

Electronics, electroplating, electrophoresis, battery, vacuum coating, detergent, cosmetics, glue, chemical, pigment, surface treatment, brackish water treatment, etc.

gd55光大彩票And can be applied as follows:

◇ RO pure water device as a super high pure water production of the first level desalination equipment.

◇ Electronic industry water integrated circuit, silicon chip, display tube and other electronic components, PCB flushing.

◇ Pharmaceutical industry water infusion, injections, tablets, biochemical products, equipment cleaning;

◇ Other process water for automobile, home appliance coating, coated glass, cosmetics, fine chemicals and other ultra-pure water.

1. The incoming water quality shall be municipal tap water or equivalent water source.Inlet water pressure: 0.15-0.4mpa, water temperature 5-40℃

2. Water production technical index: 6 tons /h (water temperature 25℃) reverse osmosis +EDI,

(1) Water production standard: in line with national standard A for reverse osmosis equipment (GB/T 19249-2003),

(2) the ultrapure water: resistivity 10-18.25 - M Ω/cm or more, the water temperature is 25 ℃, the TOC: 1-3 PPB, particles (> 0.22 um) < 1 / ml, microbial < 1 cfu/ml.

1. The system equipment is entitled to one-year free warranty, the warranty date is calculated from the date of product acceptance, and the consumable filter material is not listed here.

2. In case of any equipment quality problem (except caused by misoperation or unforeseen factors) during the warranty period, the supplier shall repair it free of charge and replace the damaged parts.

3. After the expiration of the warranty period, only a certain material fee and appropriate technical service fee will be charged.

4. in case of system operation failure, which can not be solved by themselves or by phone, our technical maintenance personnel shall make solutions (including temporary measures) and schedule within 24 hours after receiving the buyer's written notice of failure and report to the competent leaders of both parties.

gd55光大彩票5. After the delivery of the equipment, our company will have engineers to pay a return visit to understand the operation of the equipment and provide technical services in a timely manner. Users are welcome to ask any technical questions, and we will reply in time.

① the user shall provide detailed data of raw water test, so that our company can carry out relevant selection and arrangement calculation.

② the user shall explain the water quality requirements, use and water yield of the produced water.

③ our company has many types of pressure vessels, membranes, accessories, etc. if the user gives special instructions, we will try our best to meet the requirements.

④ our company provides installation and debugging for the designed and sold equipment and training for the user's operation personnel.

⑤ our company implements the principle of one-year equipment warranty and lifelong service for users, and establishes archives for tracking service to ensure the quality level.

If the above equipment fails to meet your requirements, please contact us, and we will formulate a detailed engineering plan based on your actual situation, to achieve a low-cost, high efficiency and scientific process combination, so that the water production can meet your ideal requirements.

- Water Treatment Equipment for Dairy Food and Wine Brewing

- Medicine, medical devices and other purified water equipment

- Solar Photovoltaic Ultra Pure Water Equipment for Electronic Chemical Industry

- Electroplating. Coating. Glue plasma deionization equipment

- Island Marine Desalination Water Treatment Equipment

- Cooling circulating water equipment for power plant smelting

- Clean the sewage treatment system

- Purified water distribution system

- Ultra pure water system for urea

- RO Reverse Osmosis Purified Water Equipment System

- Hollow Fiber Ultrafiltration Equipment for Mineral Water

- Direct Drinking Water Equipment in Hotel Residential Buildings

- Frequency Conversion Constant Pressure Water Supply System Equipment

- Water treatment equipment for rainwater and rivers and streams

- Rural, domestic and commercial water purification equipment

- Domestic water treatment equipment

- Softening water treatment equipment

- Well water treatment equipment

- Pure Water Filling Production Line

- Liquid packing machine

- Bottle Blower Series

- Heat shrinkable packaging machine

- Marking and Setting Machine

- Automatic Code Spraying Machine

- QS Certification Product Summary

- Reverse osmosis device

- Hollow Fiber Ultrafiltration Device

- EDI device

- Sterile water tank, filter, membrane shell

- Pump, Flange, RO Membrane, Ultrafiltration Membrane

- Instruments, Instruments, Testers

- Pipe fittings, valves and accessories

- Quartz Sand, Activated Carbon, Yin-Yang Resin

- Chlorine dioxide generator

- Dosing device

- Oxygenerator

- Water treatment chemicals

- Distilled water machine