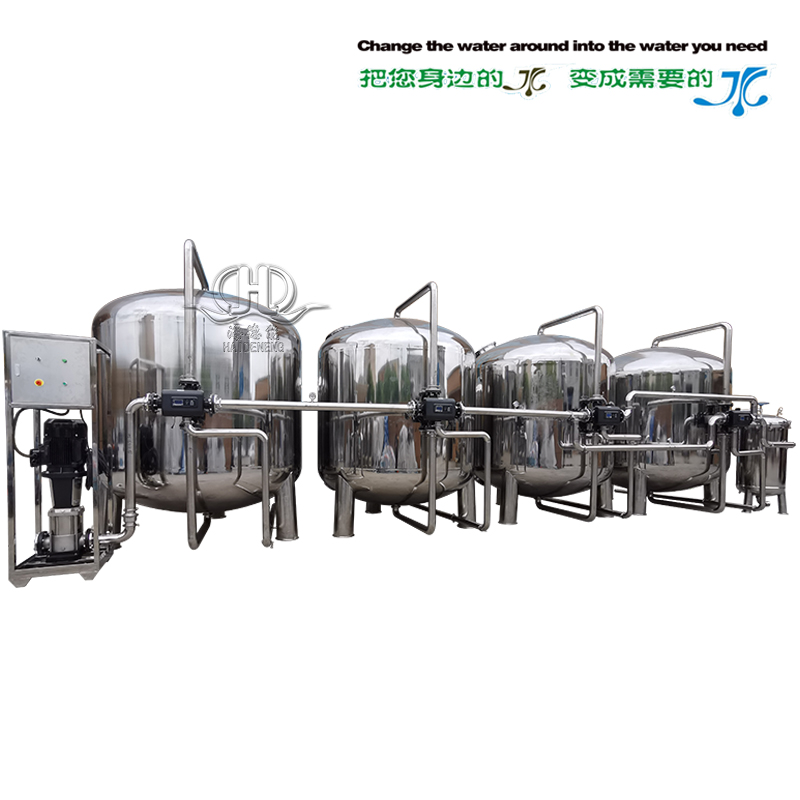

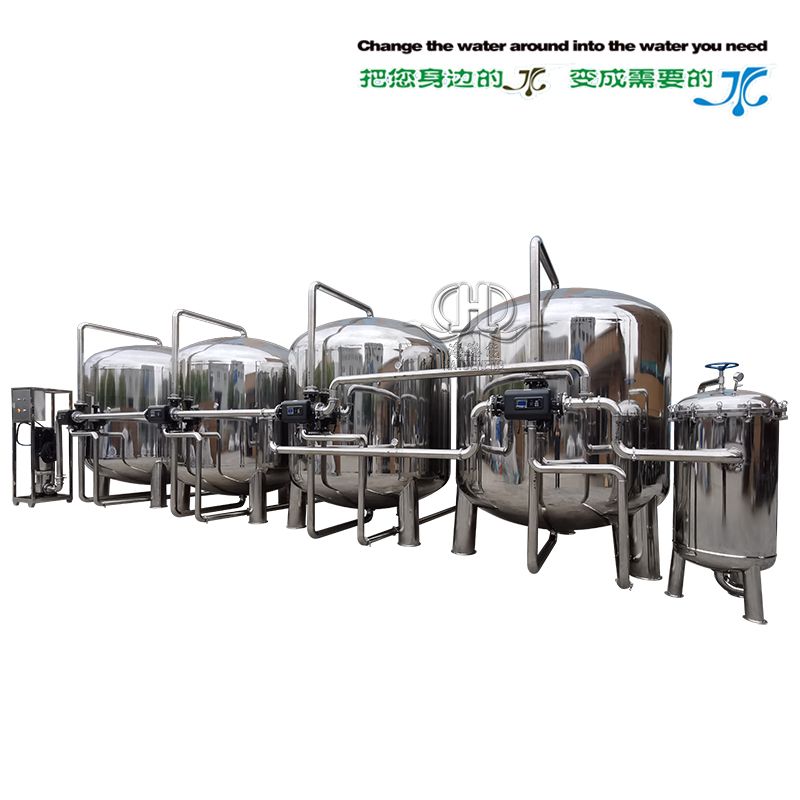

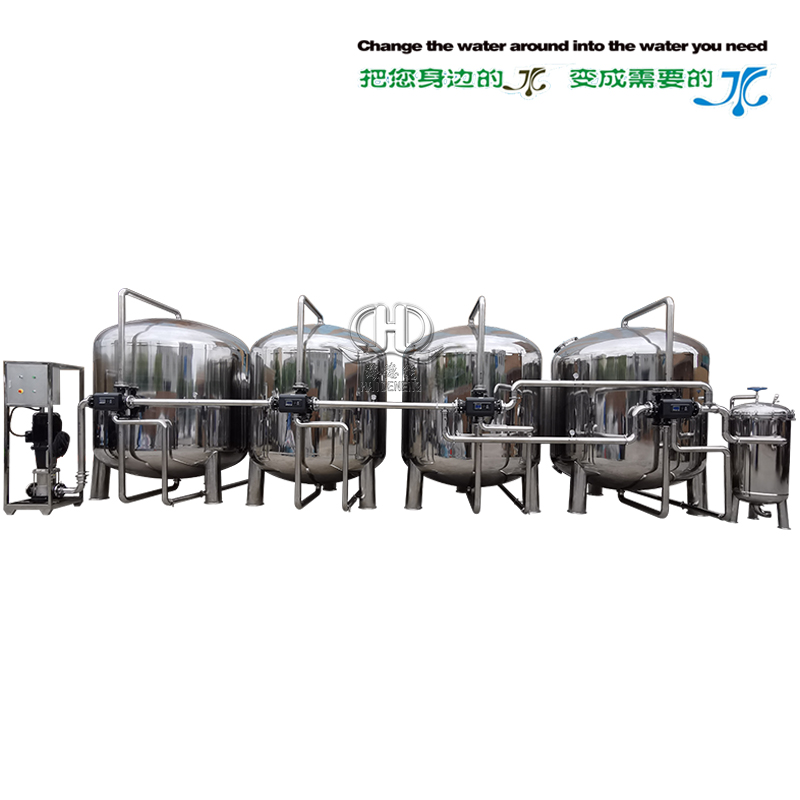

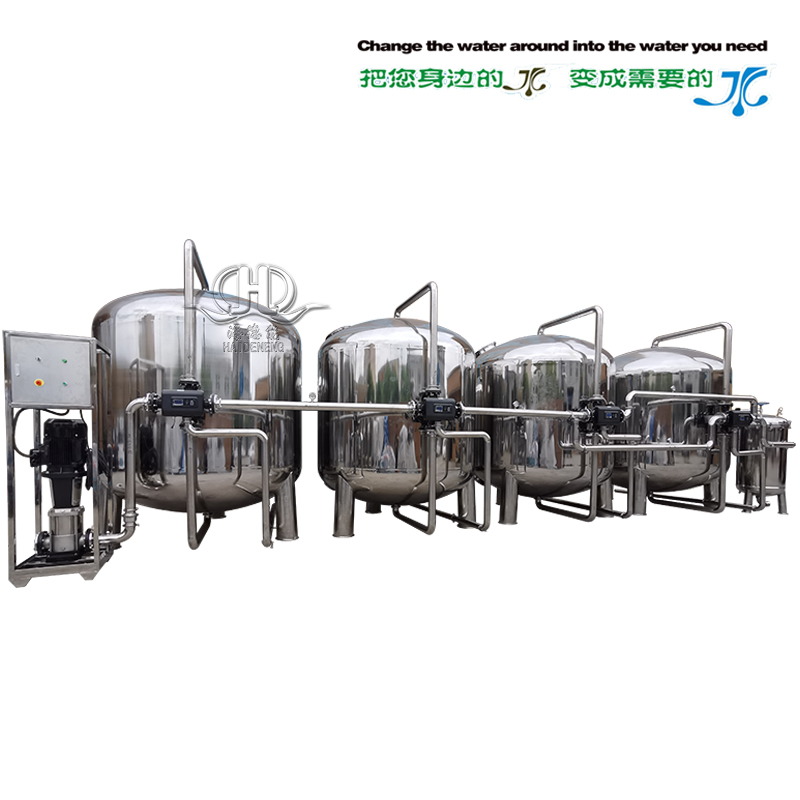

1、 Equipment name: automatic softened domestic purified water treatment system

gd55光大彩票2、 Specification and model: hdnrh-75000

gd55光大彩票3、 Equipment brand: Wenzhou Haineng wzhdn

gd55光大彩票4、 Product function description:

1. Water softener:

gd55光大彩票The hardness of water is mainly composed of calcium (CA) and magnesium (mg) ions. When the raw water containing hardness passes through the cation resin layer of the water softener, the calcium and magnesium ions in the water are absorbed by the resin, and sodium ions are released at the same time. In this way, the water flowing out of the exchanger is the softened water which has removed the hardness ions. When the resin adsorbing calcium and magnesium ions reaches a certain degree, it will lose the exchange capacity. At this time, the water softener will automatically regenerate the failed resin according to the predetermined procedure, and use the high concentration of sodium chloride solution to pass through the resin to restore the failed resin to the sodium resin.

gd55光大彩票2. Runxin control valve: the valve body is made of high strength light anti-corrosion engineering plastic and lead-free brass.

3. Anti corrosion tank: the tank body is made of glass fiber reinforced plastic (carbon steel or stainless steel lined with plastic tank body can be selected). The tank body is anticorrosive, pressure resistant and has a long service life.

4. Uniform water distribution system: using jet water distribution, the effective exchange capacity of resin can be brought into full play, accurate control with salt, no salt pump is needed.

gd55光大彩票5. Imported high performance resin: select strong acid cation exchange resin, low damage rate, uniform particle size, improve ion exchange rate.

6. Softener working procedure:

Water is supplied first, and the untreated water passes through the resin layer, and exchange reaction occurs to produce soft water. Then backwash, water enters from the lower part of the resin layer to loosen the resin and remove the fine debris. Then into brine regeneration: using high concentration of salt water (NaCl) to flow through the resin, the invalid resin will be reduced to sodium resin again. Then flushing: according to the process of water supply, the excess salt solution and calcium and magnesium ions exchanged by regeneration are washed off by water through resin. Finally, water is injected into the salt tank to dissolve salt for the next regeneration.

7. Softener installation requirements:

(1) The foundation shall be horizontal, and floor drain or drainage ditch shall be set nearby to drain the regenerated wastewater. Independent power socket shall be set near the equipment.

(2) The salt tank should be close to the exchange tank, and the shorter the salt suction pipe, the better.

(3) Y-type filter and water meter should be installed on the inlet pipe, and the sampling port should be set at the outlet.

(4) Manual valves should be installed on the inlet and outlet pipes, and a bypass valve should be set between the inlet and outlet, so as to continue water supply during regeneration or maintenance.

(5) If the water pressure at the water inlet is lower than 0.2MPa, an automatic booster pump shall be added.

gd55光大彩票(6) The salt in the salt tank is required to be industrial salt, and iodized salt and calcium salt are not allowed to be added. In order to ensure that the concentration of salt solution in the salt tank can reach saturation, the dissolving time should be no less than 6 hours, and forced regeneration should be performed before the first use.

(7) When the raw water hardness>When 6mmol / L, 1-2 grade selection should be increased.

gd55光大彩票(8) Before use, the pipeline must be flushed to avoid impurities blocking the valve body and polluting the resin.

(9) Anti freezing measures should be taken in winter in North China.

8. Time control:

gd55光大彩票The regeneration cycle is set according to the hourly output and periodic water production. It is generally suitable for occasions with stable water consumption.

9. Flow control:

gd55光大彩票The regeneration program is started according to the periodic water supply. During the operation of the equipment, the total water production is counted by the special flowmeter. When the total water production reaches the set periodic water supply, the controller starts the regeneration program for automatic regeneration. The regeneration of the equipment has nothing to do with the operation time, which is generally suitable for the occasions of unstable water consumption and continuous water consumption.

Five. Equipment parameters:

◇ Working pressure: 0.2-0.5 MPa

◇ Water hardness: ≤ 6mmol / L

◇ Water hardness: 0.03mmol/l

◇ Working temperature: 2 ℃ - 50 ℃

gd55光大彩票◇ Power supply: AC380V, 100A, 50Hz

◇ Power: 88kw

gd55光大彩票It is widely used to soften the make-up water of steam boiler, hot water boiler, exchanger, evaporative condenser, air conditioner, direct fired engine and other systems. It can also be used for the treatment of domestic water in hotels, restaurants, office buildings, apartments, homes and other industries, as well as the treatment of softened water in food, beverage, wine making, laundry, printing and dyeing, chemical industry, medicine and other industries.

7、 Parameters to be provided for user selection:

1. Unit hourly water yield (unit: 75m3 / h)

gd55光大彩票2. Source of raw water and its total hardness, total alkalinity and total salt content

gd55光大彩票3. Water hardness: less than 0.03mmol / L)

4. The best inlet pressure (unit: MPa) is 0.25-0.35,

1. The system equipment enjoys one-year free warranty, and the warranty date is calculated from the date of product acceptance, and consumable filter materials are not included.

2. In case of equipment quality problems (except caused by misoperation or unforeseen factors) within the warranty period, the supplier shall repair the equipment free of charge and be responsible for replacing the damaged parts.

3. After the expiration of the warranty period, only a certain amount of material fee and appropriate technical service fee will be charged.

4. In case of system failure, which cannot be solved by itself or by telephone, our technical maintenance personnel shall make solutions (including temporary measures) and schedule within 24 hours after receiving the written notice from the demander, and report to the competent leaders of both parties.

5. After the delivery of the equipment, our company will have engineers to pay a return visit to understand the operation of the equipment and provide technical services in a timely manner. We welcome any technical questions and we will reply in time.

(1) the user shall provide the detailed data of raw water test, so that our company can carry out relevant selection and arrangement calculation.

(2) the user shall explain the water quality requirements, use and water yield.

(3) Our company has a variety of pressure vessels, membranes, accessories, etc. if the user gives special instructions, we will try our best to meet the requirements.

(4) our company provides installation and debugging for the designed and sold equipment and training for users' operation personnel.

(5) our company implements the principle of one-year warranty and life-long service for users, establishes files and provides tracking service to ensure the quality level.

gd55光大彩票If the above-mentioned equipment fails to meet your requirements, please contact us. We will formulate detailed engineering scheme according to your actual situation to realize low-cost, high-efficiency and scientific process combination, so as to make water production meet your ideal requirements.

- Water Treatment Equipment for Dairy Food and Wine Brewing

- Medicine, medical devices and other purified water equipment

- Solar Photovoltaic Ultra Pure Water Equipment for Electronic Chemical Industry

- Electroplating. Coating. Glue plasma deionization equipment

- Island Marine Desalination Water Treatment Equipment

- Cooling circulating water equipment for power plant smelting

- Clean the sewage treatment system

- Purified water distribution system

- Ultra pure water system for urea

- RO Reverse Osmosis Purified Water Equipment System

- Hollow Fiber Ultrafiltration Equipment for Mineral Water

- Direct Drinking Water Equipment in Hotel Residential Buildings

- Frequency Conversion Constant Pressure Water Supply System Equipment

- Water treatment equipment for rainwater and rivers and streams

- Rural, domestic and commercial water purification equipment

- Domestic water treatment equipment

- Softening water treatment equipment

- Well water treatment equipment

- Pure Water Filling Production Line

- Liquid packing machine

- Bottle Blower Series

- Heat shrinkable packaging machine

- Marking and Setting Machine

- Automatic Code Spraying Machine

- QS Certification Product Summary

- Reverse osmosis device

- Hollow Fiber Ultrafiltration Device

- EDI device

- Sterile water tank, filter, membrane shell

- Pump, Flange, RO Membrane, Ultrafiltration Membrane

- Instruments, Instruments, Testers

- Pipe fittings, valves and accessories

- Quartz Sand, Activated Carbon, Yin-Yang Resin

- Chlorine dioxide generator

- Dosing device

- Oxygenerator

- Water treatment chemicals

- Distilled water machine