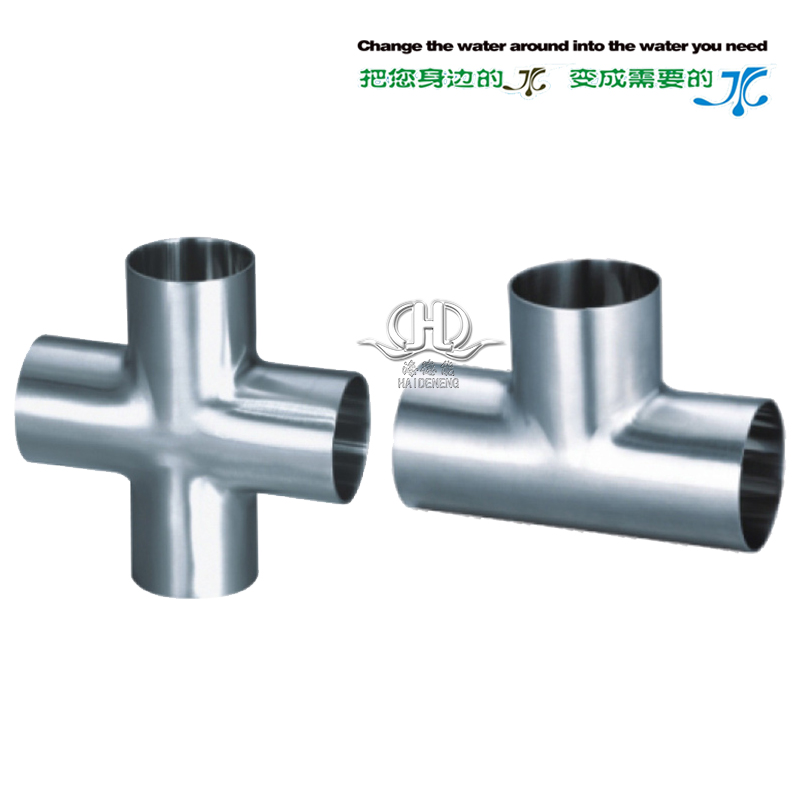

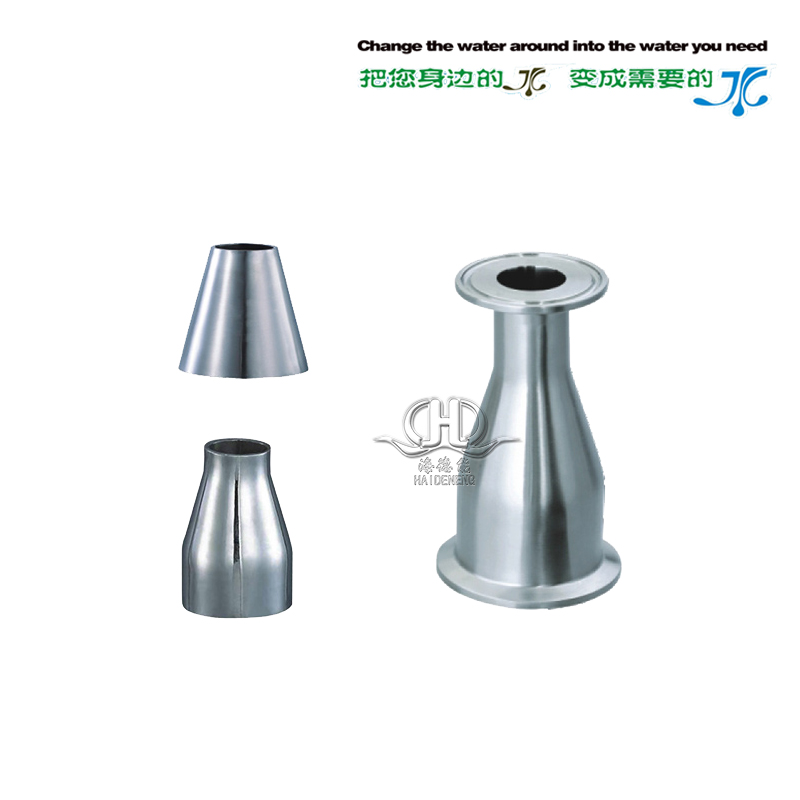

1、 Equipment name: pipe fittings (welding elbow, welding tee and cross, welding reducer, quick assembly elbow, quick assembly tee and cross)

gd55光大彩票2、 Specification and model: hdn

3、 Equipment brand: Wenzhou Haineng wzhdn

4、 Product Description:

gd55光大彩票In order to transport liquid, all kinds of pipes must be used. In addition to the straight pipe general steel pipe, various pipe fittings should be used: elbows must be used when the pipe bends, the big and small head should be used when the pipe diameter is changed, and the three-way four-way pipe fittings should be used when bifurcating. The equipment of our company adopts SUS304 stainless steel pipe fittings. The inner and outer walls of the pipe fittings should be smooth, and there are no bubbles, cracks, obvious marks, depressions, etc Uneven color and decomposition color line, pipe ends should be cut flat.

5、 General knowledge of metal materials:

Metal materials are the most widely used materials in our daily life and industry. They are mainly divided into steel, iron and non-ferrous metals. Among them, steel is the most widely used material. The main component of steel is iron, and the rest are alloy elements and various impurities added artificially. It is because of the variety and quantity of these added alloying elements that a variety of steels are formed, such as ordinary carbon steel, stainless steel, alloy steel and so on. Among these added elements, carbon (c) plays a very important role.

6、 Chemical elements:

gd55光大彩票In addition to the iron element (FE), which accounts for the majority of all kinds of steels, it usually contains the following elements (commonly referred to as alloy elements in steel)

C, Si, Mn, P, s, Cr, Ni, Mo, Ti, V, etc. In general, P and s are impurities, the lower the steel quality, the better.

gd55光大彩票7、 General knowledge of pipe materials:

◇ Material:

gd55光大彩票This mainly refers to circular pipe, which can be divided into welded pipe (straight seam welded pipe, spiral welded pipe) and seamless pipe. Welded pipe (also known as seamless pipe) is usually used for pipes with low pressure (20kg / cm? 2). Among them, spiral welded pipe is mainly used for large diameter (such as dn400 or above) system. Therefore, its wall thickness is generally thin (usually less than sch10), and seamless pipe is generally used for pipeline with high pressure Due to the limitation of pipe production process, the commonly used industrial seamless pipe is usually hot rolled, so the wall thickness of seamless pipe can be hot rolled. For a certain diameter of pipe, there is usually a certain off-line (generally higher than sch10).

8、 Stainless steel fittings:

Stainless steel pipe fittings belong to a kind of pipe fittings. They are made of stainless steel, so they are called stainless steel pipe fittings. They include: stainless steel elbow, stainless steel tee, stainless steel four-way, stainless steel reducer, stainless steel pipe cap, etc. according to the connection method, they can be divided into socket type stainless steel pipe fittings, threaded stainless steel pipe fittings, flange stainless steel pipe fittings and welded stainless steel pipe fittings. The stainless steel elbow is used for the turning of pipe fittings, the stainless steel cross pipe is used for the gathering place of four pipes, and the stainless steel reducing pipe is used for the connection of two pipes with different diameters. Main stainless steel materials: 304, 304L, 316, 316L.

1. The system equipment enjoys one-year free warranty, and the warranty date is calculated from the date of product acceptance, and consumable filter materials are not included.

2. In case of equipment quality problems (except caused by misoperation or unforeseen factors) within the warranty period, the supplier shall repair the equipment free of charge and be responsible for replacing the damaged parts.

3. After the expiration of the warranty period, only a certain amount of material fee and appropriate technical service fee will be charged.

4. In case of system failure, which cannot be solved by itself or by telephone, our technical maintenance personnel shall make solutions (including temporary measures) and schedule within 24 hours after receiving the written notice from the demander, and report to the competent leaders of both parties.

5. After the delivery of the equipment, our company will have engineers to pay a return visit to understand the operation of the equipment and provide technical services in a timely manner. We welcome any technical questions and we will reply in time.

(1) the user shall provide the detailed data of raw water test, so that our company can carry out relevant selection and arrangement calculation.

(2) the user shall explain the water quality requirements, use and water yield.

(3) Our company has a variety of pressure vessels, membranes, accessories, etc. if the user gives special instructions, we will try our best to meet the requirements.

(4) our company provides installation and debugging for the designed and sold equipment and training for users' operation personnel.

(5) our company implements the principle of one-year warranty and life-long service for users, establishes files and provides tracking service to ensure the quality level.

If the above-mentioned equipment fails to meet your requirements, please contact us. We will formulate detailed engineering scheme according to your actual situation to realize low-cost, high-efficiency and scientific process combination, so as to make water production meet your ideal requirements.

- Water Treatment Equipment for Dairy Food and Wine Brewing

- Medicine, medical devices and other purified water equipment

- Solar Photovoltaic Ultra Pure Water Equipment for Electronic Chemical Industry

- Electroplating. Coating. Glue plasma deionization equipment

- Island Marine Desalination Water Treatment Equipment

- Cooling circulating water equipment for power plant smelting

- Clean the sewage treatment system

- Purified water distribution system

- Ultra pure water system for urea

- RO Reverse Osmosis Purified Water Equipment System

- Hollow Fiber Ultrafiltration Equipment for Mineral Water

- Direct Drinking Water Equipment in Hotel Residential Buildings

- Frequency Conversion Constant Pressure Water Supply System Equipment

- Water treatment equipment for rainwater and rivers and streams

- Rural, domestic and commercial water purification equipment

- Domestic water treatment equipment

- Softening water treatment equipment

- Well water treatment equipment

- Pure Water Filling Production Line

- Liquid packing machine

- Bottle Blower Series

- Heat shrinkable packaging machine

- Marking and Setting Machine

- Automatic Code Spraying Machine

- QS Certification Product Summary

- Reverse osmosis device

- Hollow Fiber Ultrafiltration Device

- EDI device

- Sterile water tank, filter, membrane shell

- Pump, Flange, RO Membrane, Ultrafiltration Membrane

- Instruments, Instruments, Testers

- Pipe fittings, valves and accessories

- Quartz Sand, Activated Carbon, Yin-Yang Resin

- Chlorine dioxide generator

- Dosing device

- Oxygenerator

- Water treatment chemicals

- Distilled water machine