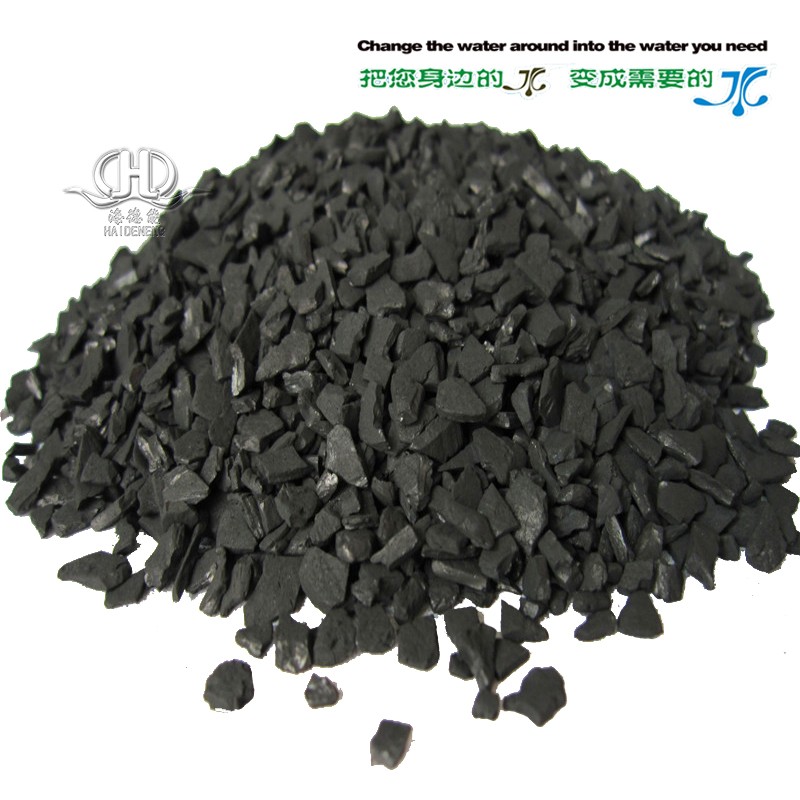

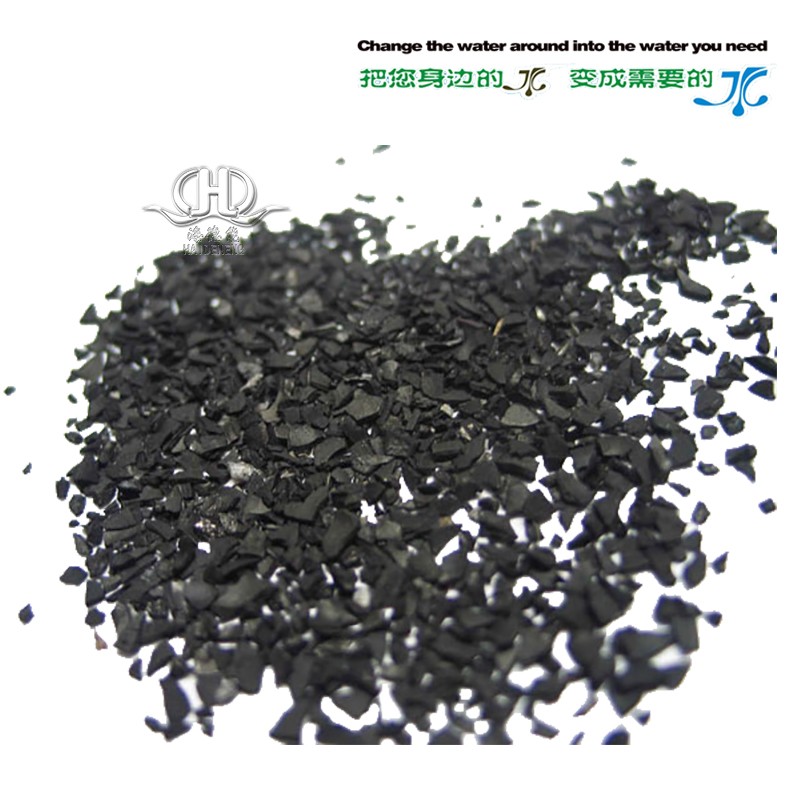

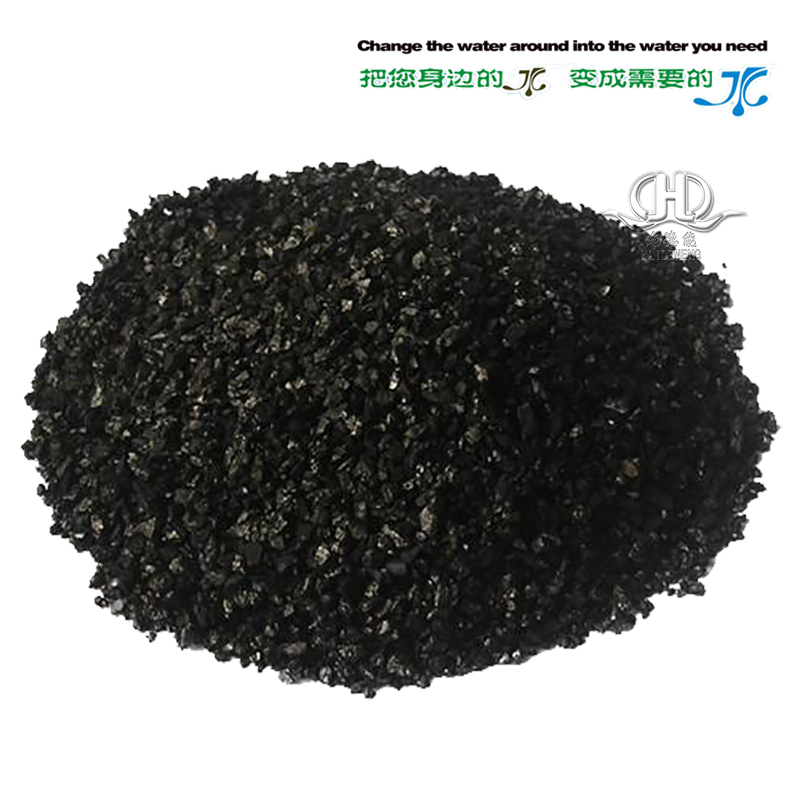

gd55光大彩票1、 Equipment name: coconut shell activated carbon

gd55光大彩票2、 Specification and model: hdn-6 ~ 12 mesh

3、 Equipment brand: Wenzhou Haineng wzhdn

4、 Product Description:

Coconut shell activated carbon is a kind of multi pore carbonized material, which has extremely rich pore structure and good adsorption performance. Its adsorption is composed of physical and chemical adsorption force, and its appearance color is black. In addition to the main carbon, its composition also contains a small amount of hydrogen, nitrogen and oxygen, and its structure looks like a hexagon. Due to the irregular hexagon structure, its polyhedral and high surface area characteristics are determined. Each gram of active carbon has a specific surface equivalent to 1000 square meters. Coconut shell activated carbon is made from high quality coconut shell by physical method. It is characterized by large specific surface area, high strength, uniform particle size, developed pore structure and strong adsorption performance.

gd55光大彩票5、 Wastewater treatment:

1. Treatment of chromium containing wastewater with activated carbon:

gd55光大彩票Chromium is a large amount of metal raw material in electroplating. Hexavalent chromium in wastewater exists in different forms with different pH values. Activated carbon has a very developed microporous structure and a high specific surface area. It has a very strong physical adsorption capacity, and can effectively adsorb Cr (Ⅵ) in wastewater. There are a large number of oxygen-containing groups on the surface of activated carbon, such as hydroxyl (- OH), carboxyl (- COOH), etc., which have electrostatic adsorption function, and produce chemical adsorption on Cr (Ⅵ). It can be used to treat Cr (Ⅵ) in electroplating wastewater. The adsorbed wastewater can meet the national discharge standard. The results show that when the mass concentration of Cr (Ⅵ) in the solution is 50mg / L, pH = 3, and the adsorption time is 1.5h, the adsorption performance of activated carbon and the removal rate of Cr (Ⅵ) are the best. Therefore, the process of using activated carbon to treat chromium containing wastewater is the result of the physical adsorption, chemical adsorption and chemical reduction of Cr (Ⅵ) in solution by activated carbon. Activated carbon has stable adsorption performance, high treatment efficiency, low operating cost and certain social and economic benefits in the treatment of chromium containing wastewater.

gd55光大彩票2. Treatment of cyanide containing wastewater with activated carbon:

In industrial production, cyanide or by-product cyanide is used in wet extraction of gold and silver, production of chemical fiber, coking, synthetic ammonia, electroplating, gas production and other industries, so a certain amount of cyanide containing wastewater must be discharged in the production process. Activated carbon has been used to purify wastewater for quite a long time, and there are more and more reports about it_ The adsorption capacity of HCN on activated carbon is small, which is generally 3mgcn / GAC ~ 8mgcn / GAC, which varies with varieties, and is not cost-effective.

gd55光大彩票3. Treatment of wastewater containing mercury with activated carbon:

gd55光大彩票Activated carbon has the ability to adsorb mercury and compounds containing mercury, but its adsorption capacity is limited, so it is only suitable for the treatment of wastewater with low mercury content. If the concentration of mercury is high, it can be treated by chemical precipitation method first. After treatment, the concentration of mercury is about 1mg / L, which can reach 2-3mg / L when the concentration is high, and then it can be further treated by active carbon.

gd55光大彩票4. Treatment of phenol containing wastewater with activated carbon:

gd55光大彩票Phenolic wastewater is widely sourced from petrochemical plants, resin plants, coking plants and oil refining and chemical plants. The results show that the adsorption performance of activated carbon for phenol is good, the increase of temperature is not conducive to adsorption, so that the adsorption capacity is reduced, but the time to reach adsorption equilibrium is shortened. The amount of activated carbon and adsorption time have the best value. Under the acidic and neutral conditions, the removal rate does not change much. Under the strong alkaline condition, the phenol removal rate drops sharply. The stronger the alkaline condition, the worse the adsorption effect.

5. Treatment of methanol containing wastewater with activated carbon:

gd55光大彩票Activated carbon can adsorb methanol, but its adsorption capacity is not strong, so it is only suitable for the treatment of wastewater with low methanol content. The operation results show that the COD of the mixture can be reduced from 40 mg / L to less than 12 mg / L, and the removal rate of methanol can reach 93.16% - 100%. The quality of the effluent can meet the water quality requirements of the feed back to the desalted water system of the boiler.

gd55光大彩票6. Activated carbon treatment industrial drainage:

gd55光大彩票The application of activated carbon in industrial drainage can be divided into two situations: more industrial drainage and less industrial drainage. In these two cases, the use of activated carbon is different. In the case of more drainage, the drainage comes from a specific process, and the components contained in it rarely change frequently; on the contrary, in the case of less drainage, the components contained in the drainage change greatly, often different every day, even in different time periods of the day.

gd55光大彩票7. Domestic sewage treatment with activated carbon:

The importance of activated carbon in sewage treatment is also an essential filter material in sewage treatment. Activated carbon is a kind of adsorbent widely used in sewage treatment.At present, China's urban domestic sewage discharge is increasing year by year at the rate of 5%. Therefore, the current treatment of domestic sewage is the primary goal to solve environmental problems.The history of the treatment of water with powdered activated carbon purification technology has reached 70 years. Since the first application of powdered activated carbon in the United States to eliminate the smell brought by chlorophenol, the effective way to remove impurities in water is still activated carbon purification technology, its purification effect has been the first in many countries.At present, China has been looking for ways to prepare activated

gd55光大彩票6、 Adsorption performance:

When coconut shell activated carbon is wet with water or circulating gas, the adsorption rate of organic solvent by coconut shell activated carbon will generally decrease. However, by using coconut shell activated carbon which can maintain a considerable adsorption capacity in the wet state, it can still be used for recycling under the condition that it is not suitable for recycling up to now, and it can save water vapor. Especially in the case of solvent recovery due to oxidation and decomposition, it can inhibit coconut shell by humidifying the adsorption gas When the temperature of the activated carbon layer increases, the reaction is inhibited, the ignition is prevented and the ketone solvent is collected, this becomes an important condition for the selection of coconut shell activated carbon. The breakthrough curve of dry coconut shell activated carbon and wet coconut shell activated carbon is different when they adsorb acetone; the breakthrough time is also one of the most important indicators of the adsorption capacity of coconut shell activated carbon.

Fruit shell activated carbon is widely used in the deep purification of drinking water, industrial water and waste water, industrial water purification and gas adsorption, such as power plant, petrochemical, oil refinery, food and beverage, sugar and alcohol production, medicine, electronics, fish farming, shipping and other industries. It can effectively absorb free chlorine, phenol, sulfur and other organic pollutants in water, especially mutagens (t HM) to achieve purification and odor removal. It can also be used for industrial tail gas purification, gas desulfurization, oil catalytic reforming, gas separation, PSA, air drying, food preservation, gas mask, disintermediation carrier, industrial solvent filtration, decolorization, purification, etc. Separation, purification and purification of various gases; recovery of organic solvents; decolorization, deodorization and purification of sugar, monosodium glutamate, medicine, alcohol and beverage; extraction of precious metals; catalysts and catalyst carriers in the chemical industry. The product has functions of decolorization, purification, impurity removal, deodorization, odor removal, carrier, purification, recovery, etc.

8、 Precautions:

gd55光大彩票1. Coconut shell activated carbon shall not be mixed with hard substances during transportation, and shall not be stepped on or stepped on, so as to prevent carbon particles from crushing and affecting the quality.

gd55光大彩票2. Storage should be stored in porous adsorbent, so in the process of transportation, storage and use, it is absolutely necessary to prevent water immersion, because after water immersion, a large amount of water is filled with active voids, making it useless.

gd55光大彩票3. Coconut shell activated carbon prevents tar from being brought into the activated carbon bed in the process of use, so as to avoid blocking the gap of activated carbon and making it lose its adsorption effect. It is better to have a decoking device to purify the gas.

4. During storage or transportation, the fire-proof activated carbon shall not be in direct contact with the fire source, so as to prevent ignition. During regeneration of the activated carbon, oxygen shall be avoided and regeneration shall be complete. After regeneration, the activated carbon must be cooled down to below 80 ℃ with steam, otherwise the temperature is high, and in case of oxygen, the activated carbon will ignite.

1. The system equipment is entitled to one-year free warranty, the warranty date is calculated from the date of product acceptance, and the consumable filter material is not listed here.

2. In case of any equipment quality problem (except caused by misoperation or unforeseen factors) during the warranty period, the supplier shall repair it free of charge and replace the damaged parts.

3. After the expiration of the warranty period, only a certain material fee and appropriate technical service fee will be charged.

4. In case of system operation failure which cannot be solved by itself or by telephone, our technical maintenance personnel shall make solutions (including temporary measures) and schedule within 24 hours after receiving the written notice from the demander and report to the competent leaders of both parties.

5. After the delivery of the equipment, our company will have engineers to pay a return visit to understand the operation of the equipment and provide technical services in a timely manner. Users are welcome to ask any technical questions, and we will reply in time.

① the user shall provide detailed data of raw water test, so that our company can carry out relevant selection and arrangement calculation.

② the user shall explain the water quality requirements, use and water yield of the produced water.

③ our company has many types of pressure vessels, membranes, accessories, etc. if the user gives special instructions, we will try our best to meet the requirements.

④ our company provides installation and debugging for the designed and sold equipment and training for the user's operation personnel.

⑤ our company implements the principle of one-year equipment warranty and lifelong service for users, and establishes archives for tracking service to ensure the quality level.

If the above equipment fails to meet your requirements, please contact us, and we will make a detailed engineering plan according to your actual situation, to achieve a low-cost, high efficiency and scientific process combination, so that the water production can meet your ideal requirements.

- Water Treatment Equipment for Dairy Food and Wine Brewing

- Medicine, medical devices and other purified water equipment

- Solar Photovoltaic Ultra Pure Water Equipment for Electronic Chemical Industry

- Electroplating. Coating. Glue plasma deionization equipment

- Island Marine Desalination Water Treatment Equipment

- Cooling circulating water equipment for power plant smelting

- Clean the sewage treatment system

- Purified water distribution system

- Ultra pure water system for urea

- RO Reverse Osmosis Purified Water Equipment System

- Hollow Fiber Ultrafiltration Equipment for Mineral Water

- Direct Drinking Water Equipment in Hotel Residential Buildings

- Frequency Conversion Constant Pressure Water Supply System Equipment

- Water treatment equipment for rainwater and rivers and streams

- Rural, domestic and commercial water purification equipment

- Domestic water treatment equipment

- Softening water treatment equipment

- Well water treatment equipment

- Pure Water Filling Production Line

- Liquid packing machine

- Bottle Blower Series

- Heat shrinkable packaging machine

- Marking and Setting Machine

- Automatic Code Spraying Machine

- QS Certification Product Summary

- Reverse osmosis device

- Hollow Fiber Ultrafiltration Device

- EDI device

- Sterile water tank, filter, membrane shell

- Pump, Flange, RO Membrane, Ultrafiltration Membrane

- Instruments, Instruments, Testers

- Pipe fittings, valves and accessories

- Quartz Sand, Activated Carbon, Yin-Yang Resin

- Chlorine dioxide generator

- Dosing device

- Oxygenerator

- Water treatment chemicals

- Distilled water machine