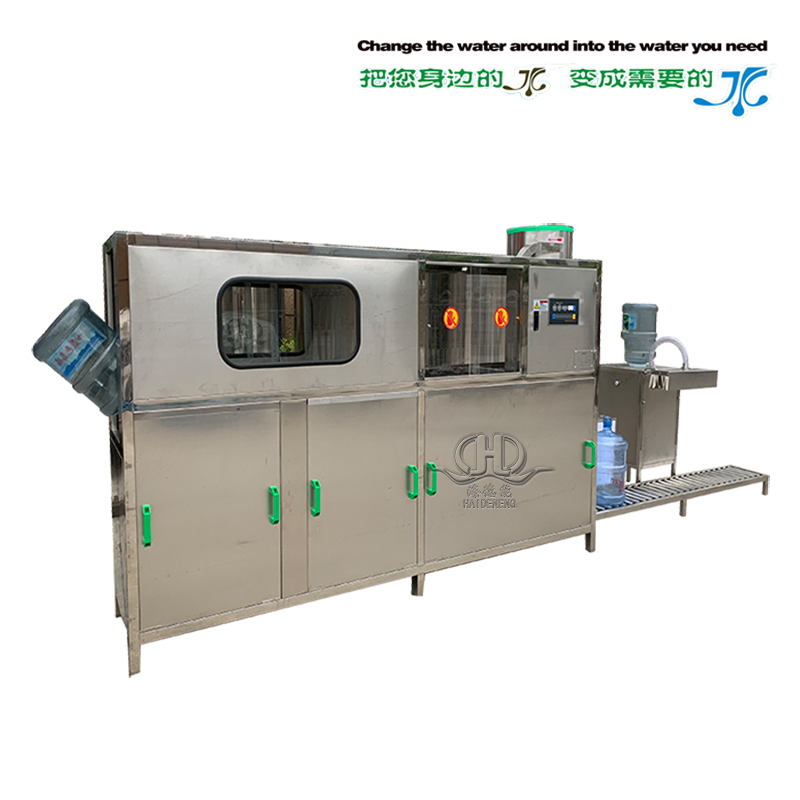

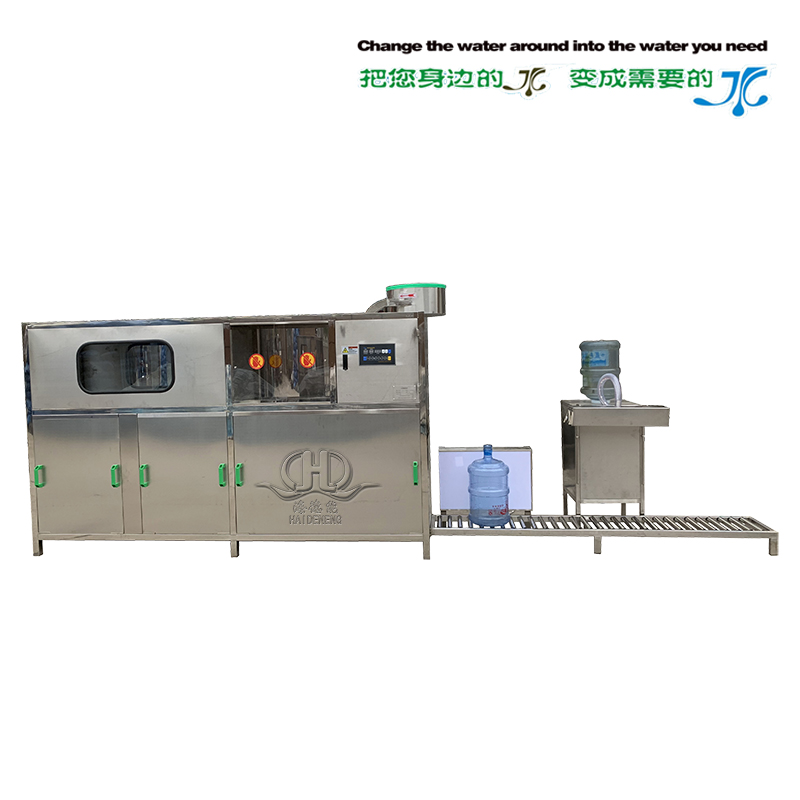

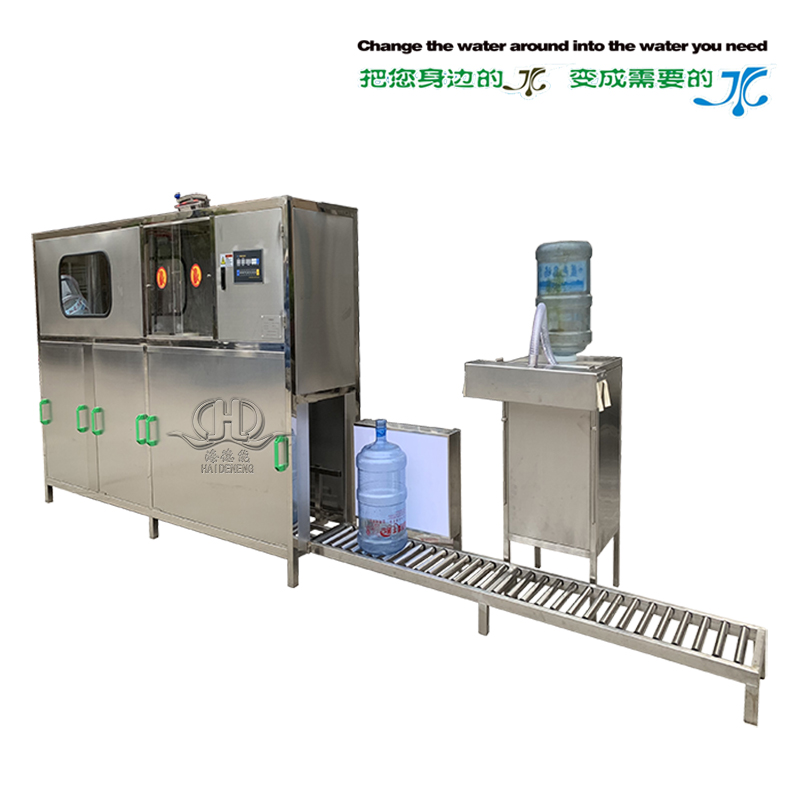

1、 Equipment name: barrel filling machine

gd55光大彩票2、 Specification and model: hdn-100-120

gd55光大彩票3、 Equipment brand: Wenzhou Haineng wzhdn

gd55光大彩票4、 Product Description:

1. Microcomputer automatic washing and filling machine is a special equipment for automatic filling of pure water. It can also be used for filling distilled water, mineral water and other sterile liquids. The equipment integrates bottle washing, filling, capping, capping and finished product delivery as one assembly line operation, effectively preventing the secondary pollution of purified water in the filling process.

2. The equipment adopts 380V (220V) 50Hz alternating current, the control system adopts advanced programmable control system and pneumatic control system programming and solidification mode, and high measurement digital display is selected. The operator can operate according to the display. Reliable performance, easy operation and maintenance.

gd55光大彩票5. working principle:

gd55光大彩票This machine adopts program full-automatic control, and its working process is as follows:

gd55光大彩票1. Bottle washing:

The second station is chlorine dioxide (ClO2 solution) washing and disinfection, the third station is pure water washing station, and the fourth station is draining station.

2. Filling:

The cleaned bottle is transported by the bottle washing driving mechanism and falls on the bottle pushing frame. The bottle pushing cylinder moves the empty bottle to the filling position and starts filling. The filling time is adjusted by the user according to the needs.

gd55光大彩票3. Cover and gland:

gd55光大彩票When the filling is finished, the filled bottle is sent to the capping mechanism by the next filling bottle, and the capped bottle is pushed to the capping mechanism and the capping cylinder to compress the cap. So far, a washing and filling cycle is completed.

6、Structural features:

The machine structure is divided into four parts:

gd55光大彩票1. Bottle washing part:

The bottle washing part is composed of bottle washing driving mechanism, bottle holder, bottle washing water pump, drug water tank, clean water bottle washing and filling water pump, bottle washing driving cylinder, etc.

2. Filling part:

The utility model is composed of a bottle pushing cylinder, a bottle pushing mechanism, a bottle discharging raceway, a filling pneumatic valve, a solenoid valve, a lid regulating motor, a lid regulating mechanism, a gland mechanism, etc.

gd55光大彩票3. Electrical part:

It is composed of PLC, AC contactor out, PLC and other parts.

4. System key Description:

This computer provides 12 operation keys, each of which will be accompanied by a beep signal prompt, and then press this key to set off.

gd55光大彩票7、 Technical parameters:

1. working voltagegd55光大彩票:AC220V 、380V (+10%,-10%)50HZ

gd55光大彩票2. Output capacity: 24V, 9V

3. Working temperature: 5-45. C

4. Working humidity: 40% - 95% (non condensing)

gd55光大彩票5. Anti interference: in accordance with iec-801 gb98813

gd55光大彩票6. Production capacity: 120-300 barrels / h

gd55光大彩票7. Filling capacity: 18.9l (5 gallons)

8. Specification of barrel and bottle: Φ 270 × 490 × Φ 56

gd55光大彩票9. End specification: Φ 58 × 40

10. Motor power: flow bottle water pump 370W 380V 220V 50Hz

11. Filling water pump: 750W 380V 220V 50

(1) The system equipment is entitled to one-year free warranty, the warranty date is calculated from the date of product acceptance, and the consumable filter material is not listed here.

(2) In case of any equipment quality problem (except caused by misoperation or unforeseen factors) during the warranty period, the supplier shall repair it free of charge and replace the damaged parts.

(3) After the expiration of the warranty period, only a certain material fee and appropriate technical service fee will be charged.

(4) In case of system operation failure which cannot be solved by itself or by telephone, our technical maintenance personnel shall make solutions (including temporary measures) and schedule within 24 hours after receiving the written notice from the demander and report to the competent leaders of both parties.

(5) After the delivery of the equipment, our company will have engineers to pay a return visit to understand the operation of the equipment and provide technical services in a timely manner. Users are welcome to ask any technical questions, and we will reply in time.

① the user shall provide detailed data of raw water test, so that our company can carry out relevant selection and arrangement calculation.

② the user shall explain the water quality requirements, use and water yield of the produced water.

③ our company has many types of pressure vessels, membranes, accessories, etc. if the user gives special instructions, we will try our best to meet the requirements.

④ our company provides installation and debugging for the designed and sold equipment and training for the user's operation personnel.

⑤ our company implements the principle of one-year equipment warranty and lifelong service for users, and establishes archives for tracking service to ensure the quality level.

gd55光大彩票If the above equipment fails to meet your requirements, please contact us, and we will make a detailed engineering plan according to your actual situation, to achieve a low-cost, high efficiency and scientific process combination, so that the water production can meet your ideal requirements.

- Water Treatment Equipment for Dairy Food and Wine Brewing

- Medicine, medical devices and other purified water equipment

- Solar Photovoltaic Ultra Pure Water Equipment for Electronic Chemical Industry

- Electroplating. Coating. Glue plasma deionization equipment

- Island Marine Desalination Water Treatment Equipment

- Cooling circulating water equipment for power plant smelting

- Clean the sewage treatment system

- Purified water distribution system

- Ultra pure water system for urea

- RO Reverse Osmosis Purified Water Equipment System

- Hollow Fiber Ultrafiltration Equipment for Mineral Water

- Direct Drinking Water Equipment in Hotel Residential Buildings

- Frequency Conversion Constant Pressure Water Supply System Equipment

- Water treatment equipment for rainwater and rivers and streams

- Rural, domestic and commercial water purification equipment

- Domestic water treatment equipment

- Softening water treatment equipment

- Well water treatment equipment

- Pure Water Filling Production Line

- Liquid packing machine

- Bottle Blower Series

- Heat shrinkable packaging machine

- Marking and Setting Machine

- Automatic Code Spraying Machine

- QS Certification Product Summary

- Reverse osmosis device

- Hollow Fiber Ultrafiltration Device

- EDI device

- Sterile water tank, filter, membrane shell

- Pump, Flange, RO Membrane, Ultrafiltration Membrane

- Instruments, Instruments, Testers

- Pipe fittings, valves and accessories

- Quartz Sand, Activated Carbon, Yin-Yang Resin

- Chlorine dioxide generator

- Dosing device

- Oxygenerator

- Water treatment chemicals

- Distilled water machine